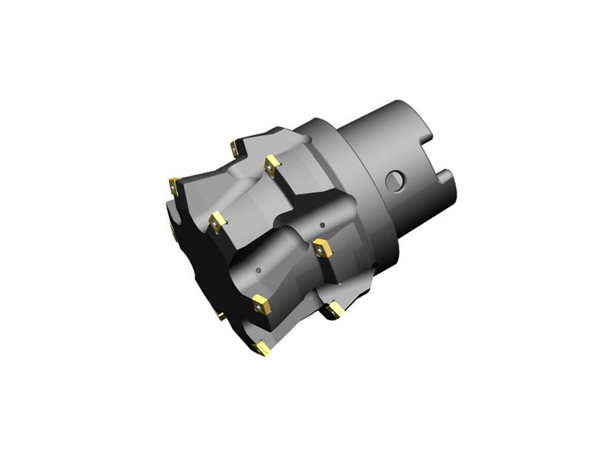

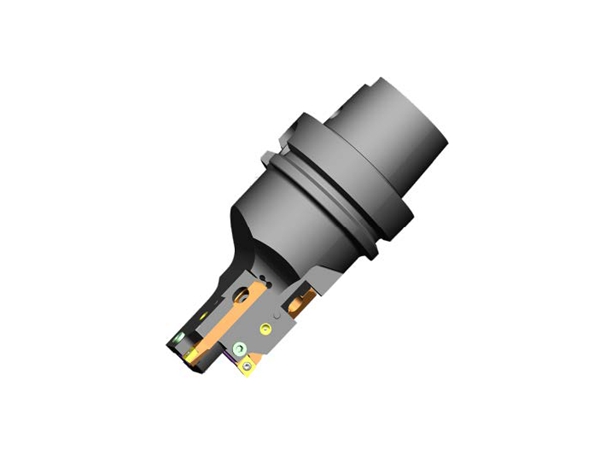

Halnn provides Customized Boring Tools tailored to meet the specific requirements of complex and high-precision machining tasks. Whether you're dealing with deep bores, special geometries, interrupted cuts, or demanding materials like hardened steel, cast iron, or alloyed components — our expert team designs boring tools that maximize machining efficiency, precision, and durability.

We offer flexible customization options including tool size, insert type, toolholder interface, cooling method, and chip evacuation strategies to perfectly fit your machining environment.

| Multi-Step Integral Sleeve Precision Boring Tool | Multi-Step Integral Sleeve Rough Boring Tool | Anti-Vibration High-Efficiency Rough Boring Tool |

|  |  |

| Anti-Vibration Damping Boring Tool | HSK High Feed Rough Boring Tool | Guide Bar Type Anti-Vibration Reaming Tool |

|  |  |

| Modular Non-Standard Custom Boring Tool | Forward and Reverse Integral Precision Boring Tool | Compound Drilling and Boring Tool |

|  |  |

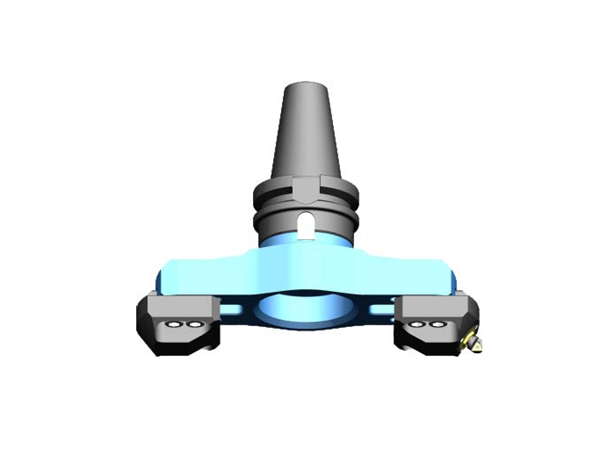

| HSK Compound Precision Boring Tool | Rough Boring Bridge Tool | Adjustable Rough Boring Tool |

|  |  |

| Cylinder Hole Machining | ||

|  |  |

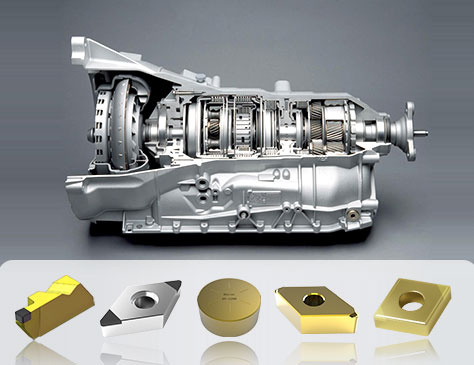

Mode:CBN tools Type:Solid CBN Insert,PCBN Insert Application:Hardened Steel

Mode:Drilling, Boring, Reaming Type:Gun Drills, Solid Carbide Drill Application:Hole Machining

Mode:Turning, Milling, Drilling, Boring Type:Crown Drill, PCD Inserts Application:Wind Energy

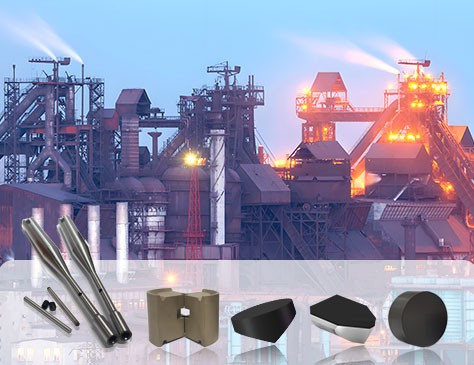

Mode:RNMN RCMX-V RCMX-Y PCD Type:BN-K1,BN-S20,CDW010 Application:Heavy Machining

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.