Halnn is a key research-supported enterprise in the fields of optical and ultra-precision machining. Our single crystal diamond (SCD) tools achieve a waviness of up to 50nm, surface roughness under 10nm, and a minimum achievable radius of just 0.01mm.

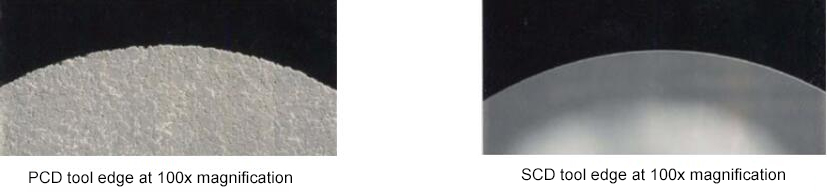

Under Metallurgical Microscope Observation:

As shown in the images below, the cutting edge of the PCD tool (left) appears jagged, while the SCD tool (right) has a smooth and continuous edge.

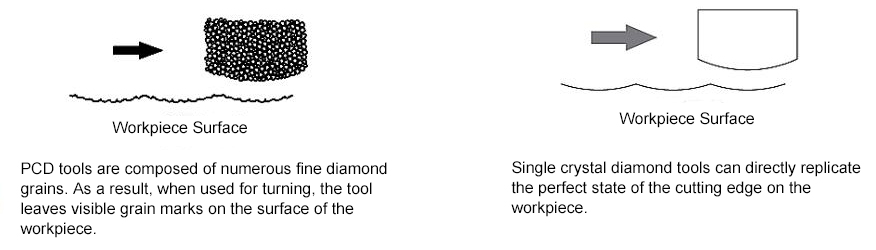

Machining Differences

Mode:Turning, Milling, Hole-making Type:PCBN Insert, PCD Tools Application:Auto Parts

Mode: Type: Application:Hydraulic industry

Mode:Drilling, Boring, Reaming Type:Gun Drills, Solid Carbide Drill Application:Hole Machining

Mode:Turning, Milling, Drilling, Boring Type:Crown Drill, PCD Inserts Application:Wind Energy

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.