The quality of the roll directly affects the working efficiency of the rolling mill, the quality and output of the rolled product, and the consumption of the roll. And as an important consumable part in the rolling process, the roll will be damaged due to many reasons in the normal rolling process. >>

When finishing hardened gears, due to the high hardness, the tool often suffers from severe wear or chipping. At this time, you can call Halnn Superhard to provide you with high-efficiency and high-quality CBN tools to ensure a long tool life. and high surface quality. >>

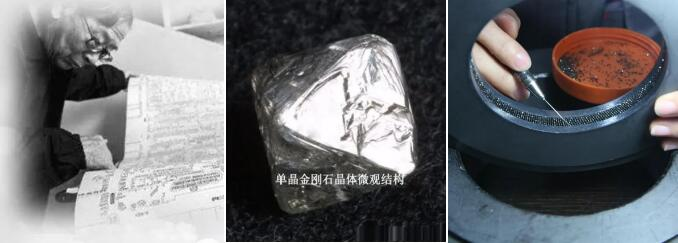

This article focuses on the classification of CBN grinding wheels and CVD diamond grinding wheels, and how CVD diamond grinding wheels dress CBN grinding wheels. >>

Halnn Superhard, as a pioneer in the localization of superhard cutting tools, developed BN-S300 and BNK30 grades, which are widely used in brake disc production lines and are well received by customers. >>

Today we will combine relevant information to talk about the internal plating manufacturing process of Electroplated diamond reamers. Electroplated diamond reamer >>

How to choose the most efficient CBN tool for processing compressors? >>

In addition to the same high strength and high modulus as resin-based composite materials, metal matrix composites can withstand high temperatures, and are non-combustible, non-moisture-absorbing, good thermal conductivity, and radiation-resistant. >>

Guide: Halnn Superhard has launched the overall pitted CBN insert for the field of brake discs and brake drums, compared with the overall CBN insert without pits. The clamping is stronger and can withstand high-speed cutting. At the same time, full veneer CBN inserts are also launched. At present, the SCGN series have successfully entered the market and are used in batches to meet the needs of semi-finishing and finishing. >>

For the ball screw, Valin Superhard launched the TNMN series of single-sided composite integral polycrystalline CBN inserts. One side and one layer are made of CBN material, without a center hole, and have both wear resistance and impact resistance toughness, which can meet the needs of rough and fine machining. More cost-effective. >>

Halnn superhard diamond rollers are currently operated independently by the [Precision Diamond Tools Division] of Halnn Corporation in accordance with the amoeba business system model, and are China’s aerospace cooperation units >>

In current market, most are aluminum alloy wheel hub. Comparing with the steel wheel hub, aluminum alloy wheel hub have the following advantages: 1. Light weight, it can reduce 30%~40% than steel wheel hub. 2.Good Shock absorption performance, absorbing impact energy, which can improve the driving performance of vehicles, improve safety performance. 3.Good thermal conductivity, the rate is about 3 times of the steel wheel hub, which can reduce the working temperature of the wheel, and improve the usage life. 4.Beautiful appearance, aluminum alloy wheel structure that produced withdifferent processes to produce can be diversified, will meet all kinds of users aesthetic requirements. >>

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.